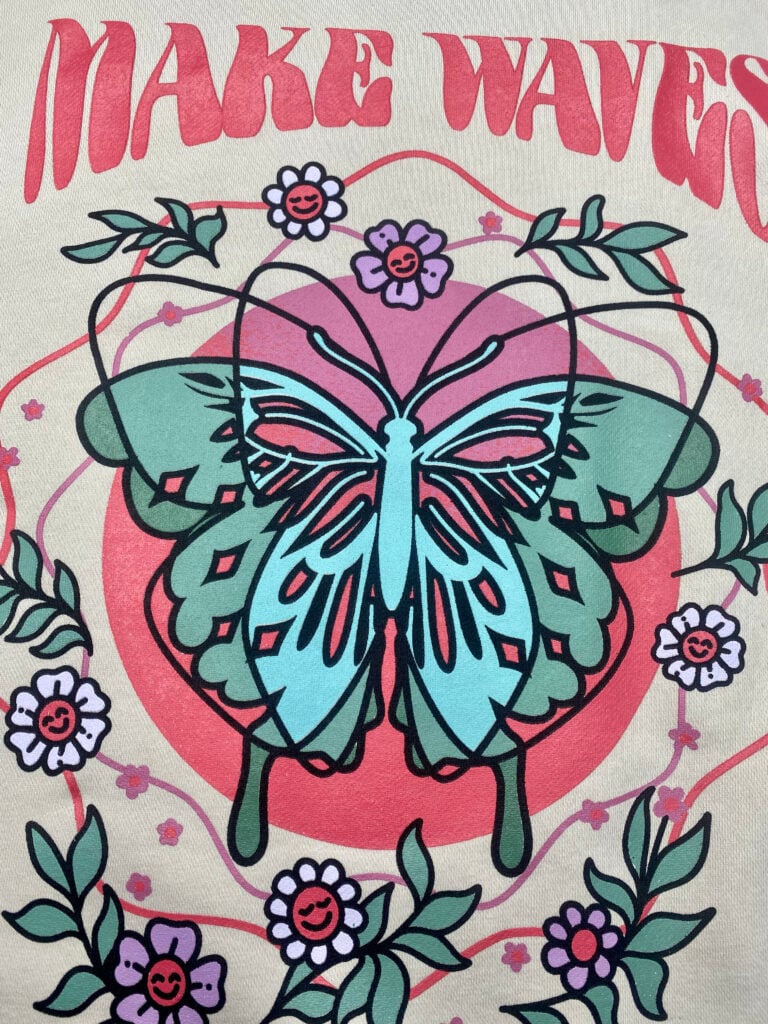

Make Merch People Actually Want to Wear

Plastisol Screen Printing

High Quality, Versatile Plastisol Screen Printing In Los Angeles

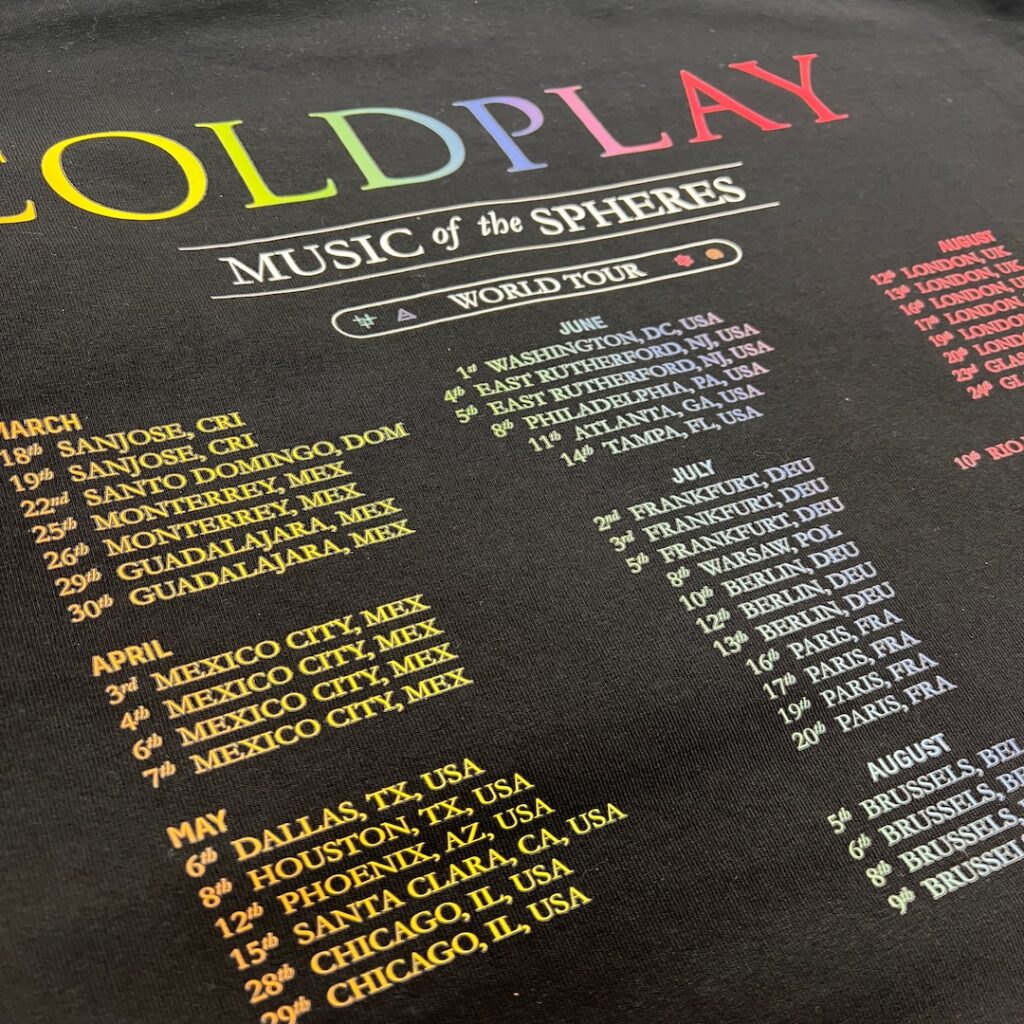

Trusted by thousands of companies across the U.S.

Vibrant Plastisol Screen Printing

What Is Plastisol Screen Printing?

If you’re wearing a custom printed shirt right now, chances are it was printed with plastisol. Plastisol screen printing has been the go to choice for branded apparel designers & manufacturers for the last 4 decades. This type of ink is the most common ink used in screen printing and for good reason. It is vibrant and provides excellent color opacity ensuring your bulk custom t-shirts is vivid even when printed on dark colored garments.

- Most durable ink option

- Multiple finishes available

- Most economical ink we offer

Plastisol Screen Printing: One Ink, Many Services.

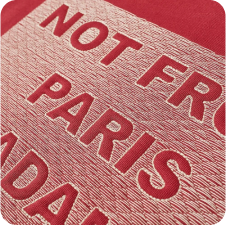

Plastisol ink is the base used for numerous services we offer. The most unique is probably Puff Ink Screen Printing, this effect is achieved by mixing in an additive that is heat reactive. Another popular service that uses plastisol is 3M Reflective Screen Printing which is made by mixing a reflective additive to the base ink.

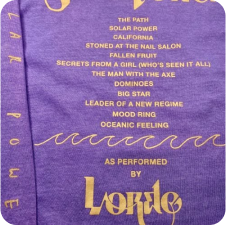

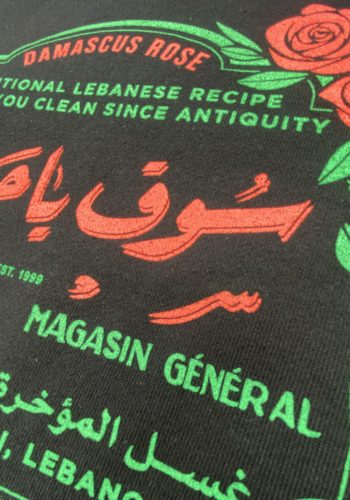

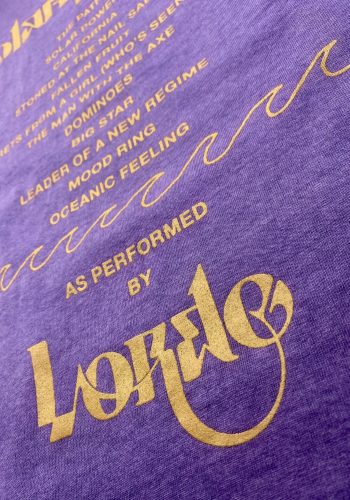

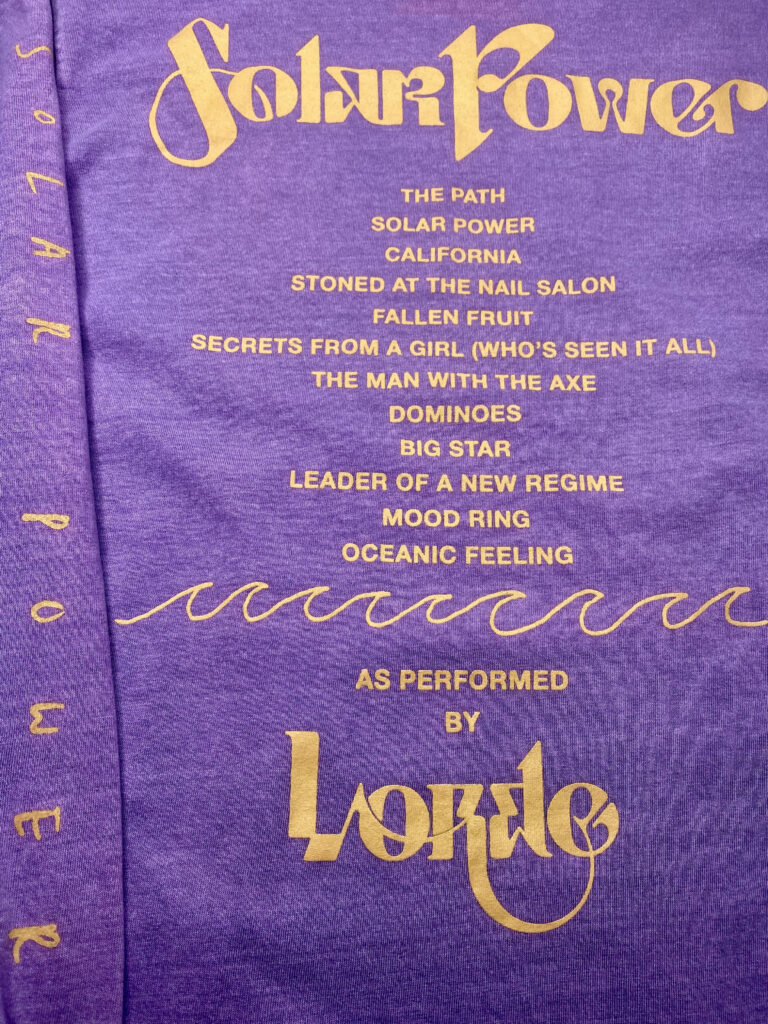

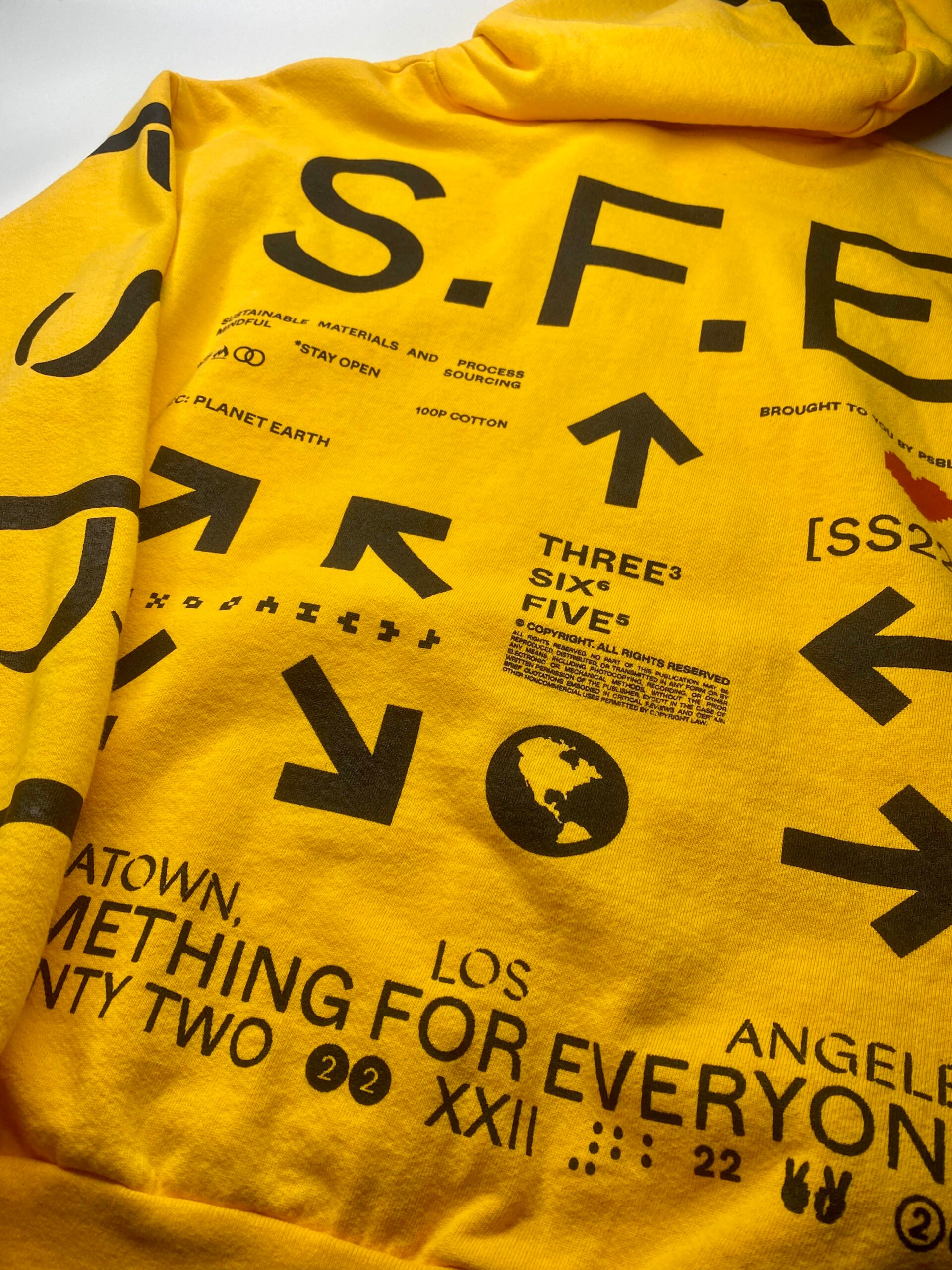

Plastisol Screen Printing Gallery

What is the Difference Between Plastisol Ink Screen Printing and Puff Print Ink?

Plastisol ink is used for the base for other multiple screen printing techniques. Puff printing is one of those services. The main difference between the two is found on a chemical level, puff ink includes a special additive that when exposed to heat causes the ink to foam, which creates the infamous puffy effect found on puff printed merch. Looking for info? One of our team members would be happy to guide you!

Plastisol

Puff

What Products are Best for Plastisol Printing?

Part of what makes plastisol such a popular ink choice is because it works well on many different materials & surfaces. As a result, plastisol ink is ideal on most products we offer. If you want to double check if a product is compatible with plastisol, don’t hesitate to reach out to one of our account reps!

Our Inks Don't Crack

How Does Plastisol Screen Printing Work?

Plastisol ink sits on top of the fibers rather than being absorbed by the material like the inks used when making a waterbased screen printed t-shirt. This allows for opaque prints that stand out against dark fabrics. They also allow for quickly layering colors, that all end up as clear and vibrant as if they were on their own.

Plastisol ink is mixed with pigments and additives to produce a butter-y thick mixture. The thick consistency is what makes this type of ink so effective. Unlike eco-friendly water based printing that is known to be quick drying, plastisol ink only changes thickness when heated. Other quicker drying inks can sometimes clog up the screen and result in a damaged print.

Unheard of Prints!

How is Plastisol Ink Cured?

After one of our master printers applies the ink, the plastisol needs to be cured to ensure the design is permanently bonded to the garment. When plastisol is exposed to temperatures of 300+ degrees, the particles in the ink melt and fuse together. This process changes the once buttery ink into a solid but flexible material that is permanently attached to your garment.

Is a Plastisol Transfer or Plastisol Printing Better?

There is no definitive answer, it depends on the goals you have for your custom merch. First, let’s explore the differences between the two services. The main difference between plastisol transfers and plastisol screen print is found in the application process. Plastisol screen prints are made when the ink is applied to the garment. In order to make a transfer the plastisol ink is applied to a clear film that is then applied to the garment with heat. We find that plastisol transfers lack definition and because of that we don’t offer them. If you’re looking to have a transfer produced, we advise using water-based transfers.

Plastisol

Water-Based Transfer

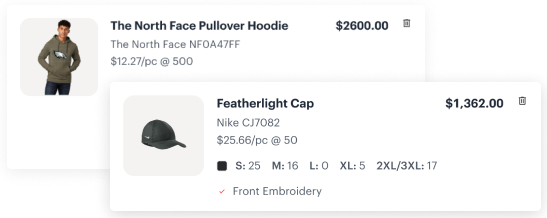

Best Sellers

-

3001

3001Bella + Canvas – Unisex Short Sleeve Jersey Tee

$5.48 - $24.66 -

5000

5000Gildan – Heavy Cotton T-Shirt

$3.97 - $21.23 -

5001

5001AS Colour – Mens Staple Tee

$8.91 - $32.39 -

1801GD

1801GDLos Angeles Apparel – S/S Garment Dye Crew Neck 6.5oz

$10.78 - $36.63 -

1717

1717Comfort Colors – Garment-Dyed Heavyweight T-Shirt

$7.65 - $18.24

-

18500

18500Gildan – Heavy Blend Hooded Sweatshirt

$17.17 - $38.45 -

5120

5120AS Colour – Mens Premium Hood

$30.39 - $58.64 -

HOOD

HOODOriginal Favorites – Organic Cotton Hooded Sweatshirt

$33.69 - $63.68 -

hf-09

hf-09Los Angeles Apparel – Ls Heavy Fleece Hood Po 14 Oz

$42.38 - $76.94 -

LS16001

LS16001Lane Seven – Unisex Urban Pullover Hooded Sweatshirt

$25.64 - $51.39

-

Sale!

Sale! 1114

1114AS Colour – Surf Cap

$6.52Original price was: $6.52.$5.54Current price is: $5.54. - $27 -

rtwlsb500

rtwlsb500Los Angeles Apparel – Poly Cotton Twill 5 Panel Hat

$15.51 - $36.93 -

5001

5001Flexfit – Adult Value Cotton Twill Cap

$7.92 - $30.17 -

6006W

6006WYupoong – Adult Classic Trucker with White Front Panel Cap

$6.00 - $25.81 -

112

112Richardson – Adjustable Snapback Trucker Cap

$7.75 - $29.77

-

600

600Bayside – USA-Made Jumbo Tote

$13.30 - $32.55 -

8502

8502Liberty Bags – Branson 6 Ounce Cotton Canvas Tote

$2.42 - $19.21 -

8861

8861Liberty Bags – 10 Ounce Gusseted Cotton Canvas Tote

$4.84 - $23.2 -

8863

8863Liberty Bags – 10 Ounce Cotton Canvas Tote with Zipper Top Closure

$6.22 - $26.32 -

1002

1002AS Colour – Shoulder Tote

$7.63 - $29.51

Plastisol Screen Printing

Frequently Asked Questions

Haven’t found what you are looking for? Email or Contact us now here

The most durable & popular option on the market for custom printed garments.

When our custom screen printed merch is printed, after ever layer of ink color, the garment is flash dried. When that happens it reaches up to 320 degrees in temperature. Once it is done going though the various screens it is then placed onto a 10ft long heated conveyor belt three separate times.

The two finishes of plastisol ink we offer are matte & glossy. If you’re looking for a sparkly or shiny finish those are differnt services known as shimmer ink or foil finish.

Absolutely not. Often times, plastisol inks are made in China out of environmentally unstable materials. We source our plastisol through trusted vendors in Italy, Japan & the US.

Yes, we offer up to 8 color prints. If you need more then 8 colors, we suggest looking into water based transfer printing.

Yes; we test and adjust the ink formulas to work on any fabrics.

If not printed or cured properly its possible, we always make sure that the formula is adjust to best fit your selected fabric.

Yes, with either a regular Plastisol base as a primary layer or a discharged waterbase for an extra smooth feel.

Receive Full Order Proofs And Eliminate Errors.

Let's Get to Work!

Start The Conversation

Your personal account rep is here to help guide and answer any questions you may have through the entire production process. Please provide a little description on how we may help. We look forward to speaking with you.

We look forward to speaking with you.

Looking for a quote? Choose “Save as a Quote Only” at checkout or try out our .