Call Us

Send Us A Message

Get a Quote

There is a 100 piece minimum to work with a sales rep.

Screen Printing: 25 pieces minimum

Embroidery: 3 pieces minimum

Water-based Transfers: 1 pieces minimum

Direct-To-Garment: 1 pieces minimum

Patches: 25 pieces minimum

Office: (323) 261-8700

9 AM - 5:30 PM PST

Chat Available 9 AM - 2 AM PST

Back

Your dedicated account rep is here to keep you updated and offer real time suggestions and project navigation every step of the way. Online ordering and live price quotes available here.

This will help us tailor the experience depending on your experience and know how to best support you.

Select one or as many of the services below you are interested in.

If you need help to identify the correct product for the correct demographic at the correct price point, select "I need help searching" and we will ask you a few additional questions to allow us to submit the best options for your project.

We want to make sure your recipients will love and wear the merch you create time and time again. These questions will really help us identify the products that will best fit your audience.

Please make sure that you have reached minimum order quantity for preferred option. MOQ descriptions you can find

DTLA Print has an in house finishing department in its facility with trained individuals to professionally fold and bag your garments. Bags can be provided with customizable options, however we use a 1 mill flat poly bag which can be air sealed or taped shut.

$0.95/Shirt

+ 2 days

Add a size sticker to the outside of each garment or poly bag to easily identify the size of a garment. Packages do come separated by size how ever many retailers and fulfillment centers do require these stickers.

$0.65/Shirt

+ 2 days

We will print & apply a custom UPC label for any retailer, 3rd party logistics or fulfillment partner you work with.

$0.75/Shirt

+ 2 days

Incorporating price tickets and hang tags securely with a pin, while offering a diverse array of sizes, colors, and finishes, significantly enhances the perceived quality and overall appeal of your garment. Additionally, not only elevate the garment’s perceived value but also provide essential product information, giving your customers a more informed and satisfying shopping experience.

$1.8/Shirt

+ 14 days

Create a fully custom woven main label. Includes the actual label itself and the sewing of the label. We will reach out to discuss the woven label material choices, shapes, and design. Please note this does add extra business days to the production time.

$2.75/Shirt

+ 14 days

Create a fully custom woven hem label. Similar to the main label, this includes the actual label itself and the sewing of the label. We will reach out to discuss the woven label material choices, shapes, and design. Please note this does add extra business days to the production time. Hem labels go anywhere except the neck label of a garment.

$1.85/Shirt

+ 14 days

4.5” W but larger can be requested

Not common, but possible

PSD, AI, PDF, EPS, PNG

12

Metallic & 3D Puff

Scaled to size or larger with transparent background

3” - 12” depending on location

15x18” *special request

PSD, AI, PDF, EPS, PNG

8

3M Reflective, Water-based, Plastisol, Puff, Etc...

Scaled to size or larger with transparent background

15x18”

PNG preferred, ( also acceptable; PSD, AI, PDF, EPS, JPG )

Unlimited

300 DPI scaled to size or larger with a transparent background

10x13.5”

PNG preferred, ( also acceptable; PSD, AI, PDF, EPS, JPG )

Unlimited

300 DPI scaled to size or larger with a transparent background

15x18”

PNG preferred, ( also acceptable; PSD, AI, PDF, EPS, JPG )

Unlimited

300 DPI scaled to size or larger with a transparent background

Upload Mockups

Don’t worry! Every order is triple checked even if it does not look perfect in this demo.

Max File Size: 15 MB. For any files larger than 15MB please send via wetransfer.com or dropbox.com and share with sales@dtlaprint.com

Tax exemption is the reduction or removal of a liability to make a compulsory payment that would otherwise be imposed by a ruling power upon persons, property, income, or transactions. Tax-exempt status may provide complete relief from taxes, reduced rates, or tax on only a portion of items. Examples include exemption of charitable organizations from property taxes and income taxes, veterans, and certain cross-border or multi-jurisdictional scenarios.

*Only orders shipped with in California are charged tax unless a a valid CA resale form is provided.

Production time is separate from shipping

If you're in a hurry to receive your order, we offer an expedited service to fast-track the production process. While this option incurs additional charges, it ensures you get your product sooner. However, if time is not a pressing concern, you can stick to our standard production schedule at no extra cost. We believe in providing you with the flexibility to choose the timeline that best suits your needs.

In the ever-evolving world of custom branded apparel printing, two methods stand out: Direct-to-Garment (DTG) printing and screen printing. Whether you’re a business owner looking to expand your printing capabilities or an artist wanting to bring your designs to life, understanding the differences, advantages, and costs associated with these methods is crucial. In this blog post, we’ll delve into the details of DTG and screen printing, helping you make an informed decision.

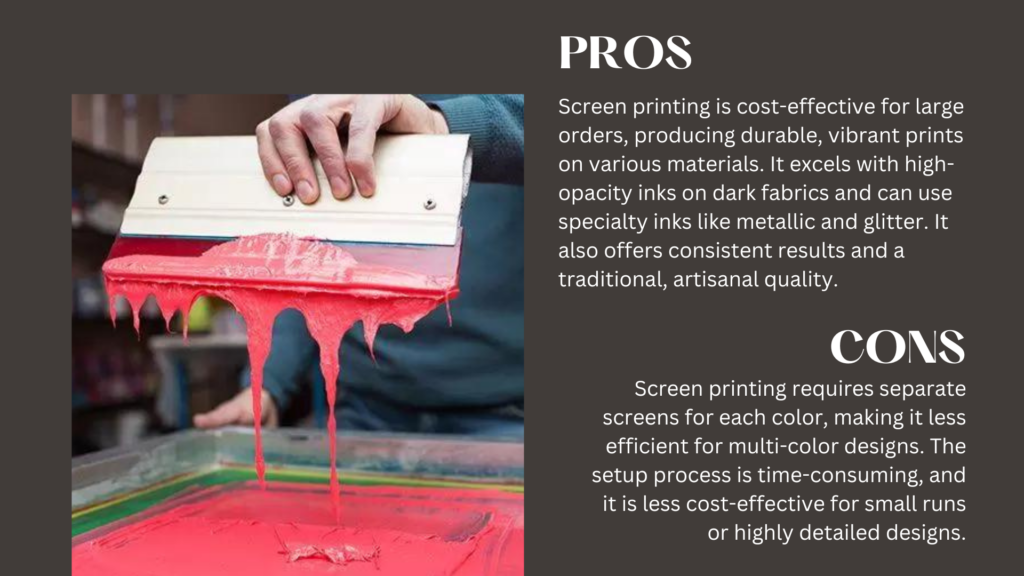

Screen printing is a traditional method that involves transferring ink onto a substrate (usually fabric) through a mesh screen that’s coated with light-sensitive emulsion. The process starts with creating a stencil (or screen) for each color in the design. Once the screens are prepared, ink is pushed through the mesh onto the fabric using a squeegee.

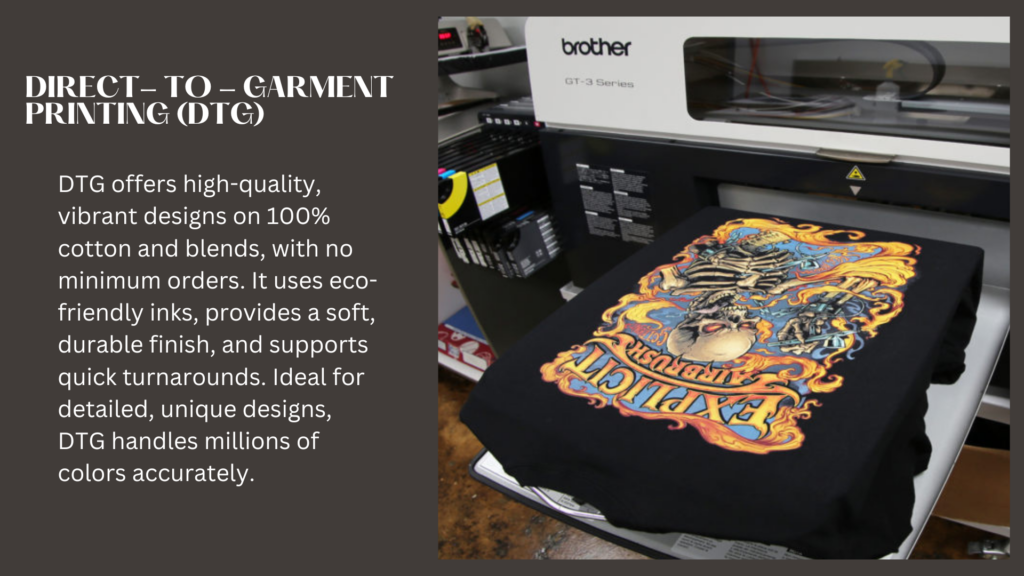

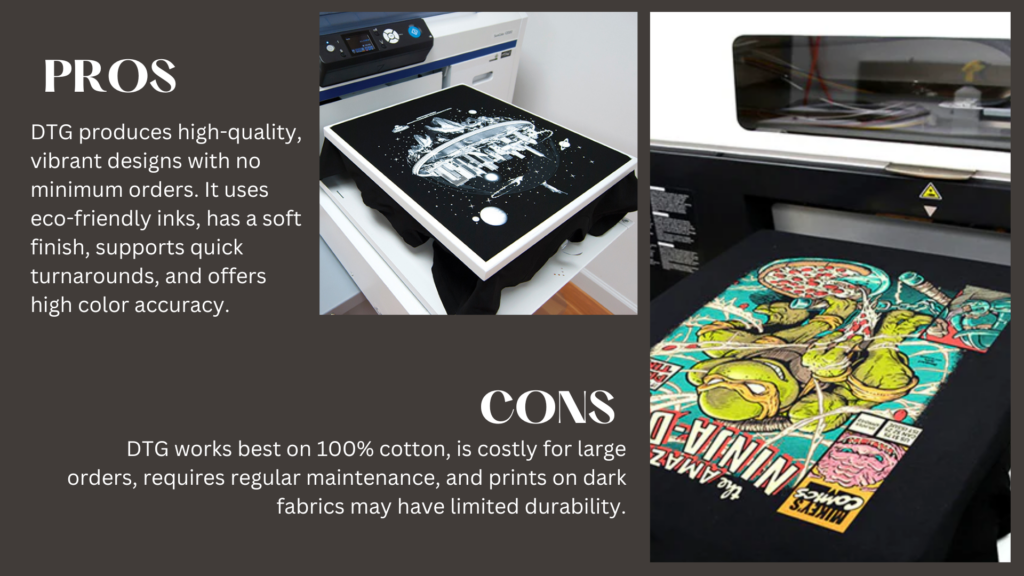

DTG printing is a more modern technique that uses a digital printer to apply ink directly onto the fabric. It’s akin to using an inkjet printer but for textiles. DTG is ideal for detailed designs and smaller orders.

When it comes to cost, several factors need to be considered, including the initial investment in equipment, ongoing costs, and the cost per print.

Screen printing is the preferred method for large orders and designs with fewer colors. It’s also ideal when vibrant, long-lasting prints are needed, especially on darker fabrics. If you have a design that can be easily separated into different color layers, screen printing will provide the best results.

DTG printing is perfect for small orders and designs with a lot of detail or color variation. It’s also a great choice for printing photographs or complex graphics directly onto garments. If you frequently receive orders with low quantities or highly detailed artwork, investing in a DTG printer can be worthwhile.

Choosing between DTG and screen printing depends largely on your specific needs. For large orders with simple designs, screen printing is cost-effective and produces durable, vibrant prints. For smaller orders or highly detailed designs, DTG offers flexibility and high-quality results despite its higher cost per print.

Both methods have their unique advantages and disadvantages, and understanding these can help you make the best decision for your printing needs.

In partnership with onetreeplanted.org

In partnership with onetreeplanted.org

Please provide the best contact number for our team to reach out to you on, your account rep will reach out within 24-48 business hours.

A 100 piece minimum is needed for an account rep to handle your order.